SmartCost มีการใช้งานคุกกี้เพื่อให้คุณได้รับประสบการณ์ที่ดีที่สุด อ่านรายละเอียดการใช้คุกกี้ของเว็บไซต์เพิ่มเติมได้ที่ นโยบายความเป็นส่วนตัว

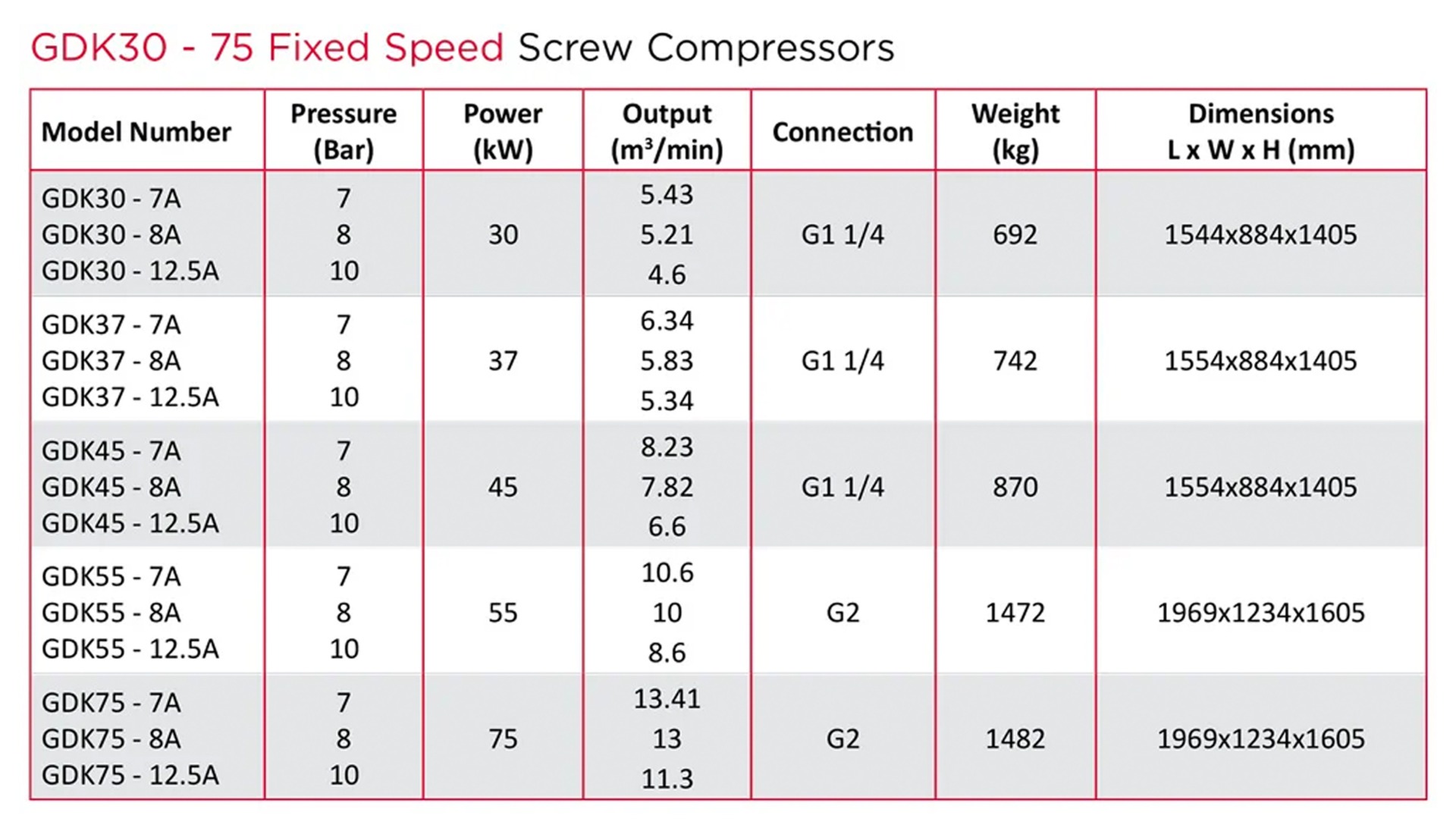

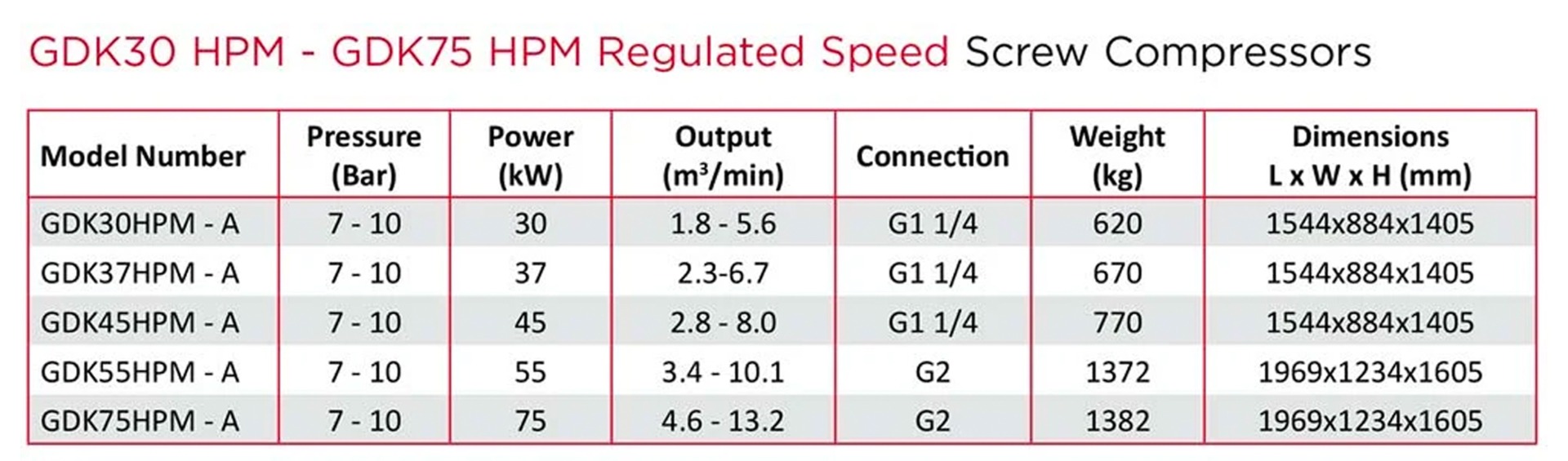

Lubricated Rotary Screw Compressors (7.5 - 75 kW)

Lubricated Rotary Screw Compressors (7.5 - 75 kW)

Key Benrfits :

Low noise levels

- Allows the compressor to be placed at the point of use

High efficiency cooling system

- Reliable operation, even in challenging environments

Self tensioning belt drive

- Eliminate the risk of belt slip or loosening

- Evenly distributing drive forces to provide balanced bearing load and belt wear

- Ensuring peak performance and extending the life of the motor and air end

Gardner Denver ผู้ผลิตเครื่องอัดอากาศ มากกว่า 100 ปี

Design :

Precision manufactured using industry leading CNC and laser measurement technology the high output compression, element coupled with highly efficient bearings and seals, make the GDK series by Gardner Denver one of the most reliable and best value performers in the market.

Controller :

The Le-120 Controller ensures safe, reliable operation. Efficiently monitoring system pressure and all critical components of your compressor. Providing a simple to use touch screen interface along with intelligent control to ensure operation is optimised to suit your compressed air needs.

Colour Touch Screen

Embedded IoT functionality

All-round protection for motors, maximum prevention of damage caused by short circuit, blocking, phase loss, overload, unbalance, etc.

Control of motor start/stop and operation

Anti-reversal protection for air compressor

Protection of temperature detection and control

Automatic adjustment of load rate and control of pressure balance

Multi-level fault alarm

Support MODBUS RTU communication protocol, flexible choice of remote/local control

RS-485 communication function allows for the outputting of remote signal to the host computer

Multi-unit sequent control enables air compressors to operate in different combinations

Local or Remote control functionality

Air Station :

Complete air stations to meet the air quality requirements of your project or site.

Packaged with high quality refrigerated air dryer and world class filtration.

Mounted on certified pressure vessels, sized for optimal performance, minimizing costly starts per hour.

Compact solutions to minimize installation foot print and cost.

Easily accessible components to make servicing simple

iConn :

The GDK Series are able to be equipped with iConn as an option. iConn is the smart, proactive real-time monitoring service that delivers in-depth and real-time knowledge on the system to our compressed air users.

It enables accurate production planning and total peace-of-mind protection, generating insight and statistics that keep users informed on performance, at the same time highlighting potential issues before they become a problem.

Condition based monitoring

Predictive maintenance required

Full Air Manufacturing Control Optimization

External data pattern integration

Performance :

Tags : ปั๊มลม, ปั้มลมสกรู, เครื่องปั๊มลม, เครื่องอัดอากาศ, Air Compressor, IR Thailland , Ingersoll Rand Thailland, เครื่องอัดอากาศโรตารี่แบบสกรู